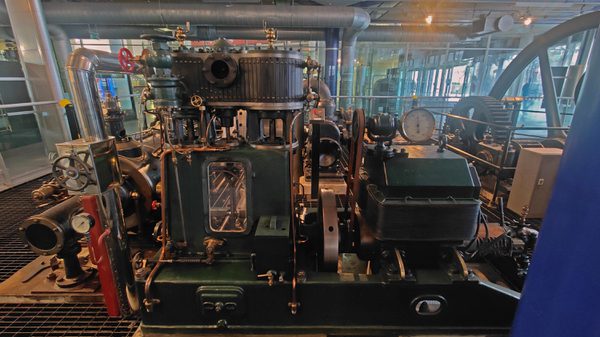

Electricity Generating Engine, c1894

Facts and Figures

- Manufacturer: G E Belliss and Co, Ledsam Street, Birmingham

- Date built: c1894

- User: R and W H Symington and Co, c1894—not known, Jarmain and Sons Ltd, dates unknown

- Period of use: c1894-1950s

- Location: R and WH Symington and Co, Market Harborough, Jarmain and Sons Ltd, Huddersfield

- Engine type: Double acting twin cylinder compound engine

- Power output: 55 horsepower / 41 kilowatts

Introduction

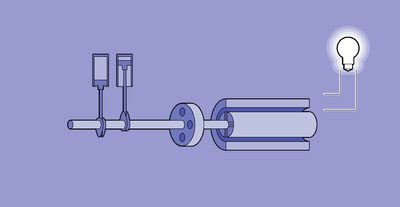

This engine was bought in 1894 to light up the works of Robert and William Henry Symington, a corset maker in Market Harborough. The process was so intricate that the 500 workers needed very bright lighting to see what they were doing. Similar engines were also used for lighting aboard Royal Navy ships. Generating electricity requires a very fast engine. It was only when this engine, with its special lubrication system, was invented in 1890, that steam engines could go fast enough to generate electricity for lighting homes and factories.

History

Most steam engines could not run at the high speed required to produce electricity. To solve this problem, Albert Pain a young engineer at Belliss and Company, invented a system called 'forced lubrication' in 1890 which involved pumping oil around the bearings to stop them being worn away. The largest engines of this type were installed at Birmingham's new Summer Lane power station in 1906. Its opening concided with the extension of electric lighting to the whole city and the electrification of the tramway system. This engine was used to light a corset factory in Market Harborough.

The firm of Robert and William Henry Symington was the creator of the factory-made corset which brought fashion within reach of the whole female population. The tight wasp-waisted corset reached its height in the early 1890s. It was not only a fashion item but also afforded respectability and status to the wearer. The firm's most famous product was the Liberty Bodice introduced in 1908. Designed to replace the corset, the new knitted material was advertised as still providing support and yet allowing total freedom of movement. Simple enough for a child to put on, it was comfortable, cheap and warm. The finished corsets were moulded into shape on copper forms, known as 'Swedish Maidens'.

What's Special